Smart Vietnam's R&D Program Paves the Way for Innovation and Excellence

Smart Vietnam stands out as a leader in the precision sheet metal fabrication industry, committed to investing heavily in research and development (R&D) to drive continuous improvement and innovation in our precision sheet metal fabrication services. Our unwavering dedication to R&D has enabled us to stay ahead of the curve and remain at the forefront of the industry, providing our customers with innovative solutions that meet their specific requirements. Our R&D program encompasses a wide range of activities.

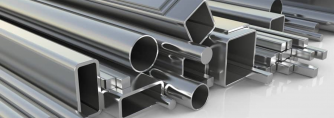

1. Materials Research

Smart Vietnam stands as a towering titan in the sheet metal fabrication industry, renowned for our unwavering commitment to materials research and our ability to work with an extensive range of materials, including carbon steel, stainless steel, spring steel, bronze, brass, copper, aluminum, cold-rolled steel, hot-rolled steel, zinc plate, and beyond. Our unparalleled expertise in these materials allows us to offer innovative solutions that meet the evolving needs of our customers, no matter how complex their requirements may be.

Our materials research process is exhaustive and thorough, involving a meticulous evaluation of each material we work with. We test and assess their compatibility with our fabrication processes and evaluate their potential benefits to our customers, such as enhanced durability, strength, and corrosion resistance. We also push the boundaries of what is possible in sheet metal fabrication by exploring new and innovative materials that can help us achieve our goals.

In addition to our expertise in materials, we also specialize in a wide range of surface finishes, including powder coating, painting, polishing, spray coating, brushing, cataphoresis, sandblasting, electroplate chrome, zinc, nickel plating, anodizing, electronic polish, and chem film. Our proficiency in these techniques allows us to enhance the aesthetic appeal and functionality of our products, resulting in solutions that meet the highest standards of quality and reliability.

At Smart Vietnam, our commitment to materials research is unparalleled, and our dedication to excellence is unmatched. We take pride in being at the forefront of the industry, constantly pushing the boundaries of what is possible in sheet metal fabrication. Whether you need a custom solution or a standard product, you can count on us to deliver the highest quality products and services that exceed your expectations and meet your unique needs.

2. Machinery and Technology Research

At Smart Vietnam, we recognize the importance of investing in cutting-edge machinery and technology to maintain our position as a leading provider of precision sheet metal fabrication services. As such, we place a strong emphasis on machinery and technology research, continuously evaluating and investing in new equipment to enhance our fabrication processes and capabilities.

To ensure we stay ahead of industry trends and advancements, we conduct ongoing research into emerging technologies and machinery. Our exploration includes a wide range of options, including Computer Numerical Control (CNC) machining, robotic automation, and Internet of Things (IoT) solutions. Additionally, we attend industry conferences and collaborate with industry experts to identify new opportunities for development and innovation.

Once we identify new machinery and technology that can benefit our operations, we subject it to rigorous evaluation and testing to ensure it meets our high standards for quality, reliability, and performance. We also carefully consider the potential benefits to our customers, such as faster turnaround times, increased precision, and improved product quality.

If we determine that an investment in new machinery or technology is warranted, we collaborate closely with our suppliers and partners to acquire and integrate it into our operations. We also provide ongoing training and support to our team members to ensure they are equipped with the skills and knowledge necessary to operate the new equipment effectively.

Our commitment to machinery and technology research has enabled us to reap a wide range of benefits. For instance, we have been able to increase efficiency and productivity by automating certain tasks and optimizing our workflows. Furthermore, investing in new machinery and technology has allowed us to expand our capabilities and take on more complex projects, enabling us to better serve our customers, reduce waste and minimize our environmental impact while improving workplace safety.

3. Process Optimization

Smart Vietnam places a strong emphasis on process optimization to drive continuous improvement in our precision sheet metal fabrication services. To optimize our fabrication processes, we conduct regular analyses of our processes, workflows, and machinery to identify areas for improvement. We use a variety of tools and techniques to evaluate our processes, including statistical process control, lean manufacturing principles, and Six Sigma methodologies. This enables us to identify bottlenecks, inefficiencies, and other areas that can be improved to increase productivity, reduce costs, and improve product quality. Once we have identified areas for improvement, we work closely with our team of engineers and technicians to develop and implement solutions such as reconfiguring our machinery and equipment, streamlining workflows, or employing new technologies to improve efficiency and quality.

4. Customer Feedback

At Smart Vietnam, we place a high value on customer feedback and use it to inform our research and development (R&D) efforts. We believe that incorporating customer feedback is essential to developing customized solutions that meet their specific needs and requirements. To incorporate customer feedback into our R&D efforts, we actively seek feedback from our customers at every stage of their engagement with us. This includes soliciting feedback during the design and development phases of a project, as well as during the production and delivery stages. We use a variety of channels to gather feedback, including surveys, feedback forms, and one-on-one interactions. Once we have collected customer feedback, we carefully analyze and evaluate it to identify areas for improvement and to inform the development of new products and services. We use this feedback to refine our fabrication processes, optimize our machinery and technology, and explore new materials and techniques that better meet our customers' needs.

Smart Vietnam firmly believes that investing in R&D is paramount to staying competitive in an ever-evolving market. Our team works tirelessly to design, test, and refine our products, ensuring that they meet the highest standards of quality and reliability. At Smart Vietnam, we recognize that our success is intertwined with the success of our customers, and we are fully committed to helping them achieve their goals through our cutting-edge products and services. Our unyielding commitment to R&D empowers us to constantly improve and innovate our offerings, ensuring that our customers receive the best possible solutions that are tailored to their unique needs.

_cr_334x118.png)

-min_cr_334x118.jpg)